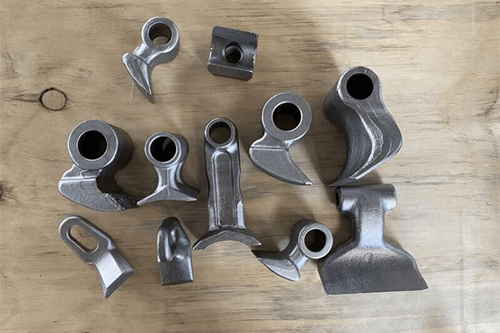

How To Keep Your Groundhog Foundation Drilling Tools Sharp

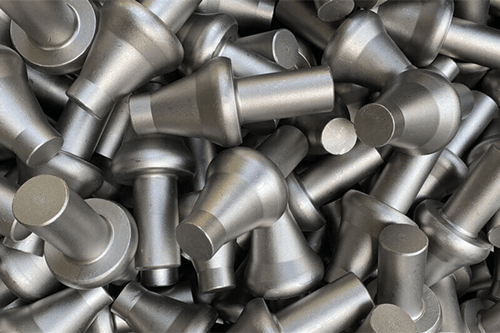

Ensuring the sharpness and effectiveness of groundhog foundation drilling tools is crucial for maintaining efficiency and safety in construction projects. Dull or worn-out tools can lead to decreased productivity, increased wear and tear on equipment, and potential safety hazards. Therefore, implementing strategies to keep these tools sharp is essential for successful operations. Here are five effective ways to maintain sharp groundhog foundation drilling tools:

Regular Inspection and Maintenance:

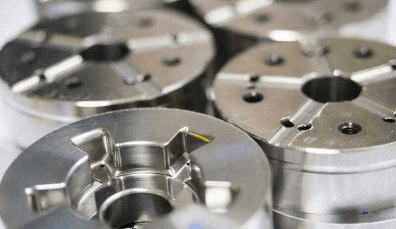

Regular inspection and maintenance routines are fundamental for keeping groundhog foundation drilling tools sharp. Begin by inspecting the tools for any signs of wear, damage, or dullness before each use. Look for chips, cracks, or excessive wear on cutting edges, teeth, or blades. Additionally, clean the tools thoroughly after each use to remove dirt, debris, and corrosion, which can contribute to dullness over time.

Proper Storage:

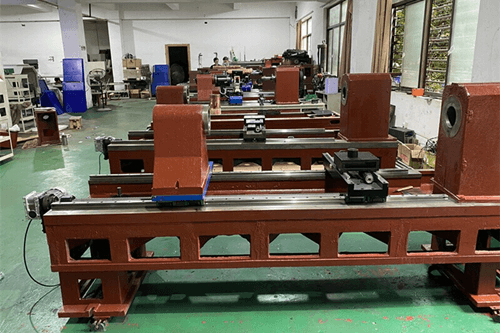

Proper storage is critical for preserving the sharpness of groundhog foundation drilling tools when not in use. Store the tools in a clean, dry environment to prevent exposure to moisture, which can lead to rust and corrosion. Use protective covers or cases to shield the tools from damage and keep them organized. Avoid storing tools in areas prone to temperature fluctuations or extreme conditions, as this can also affect their sharpness and performance.

Sharpening Techniques:

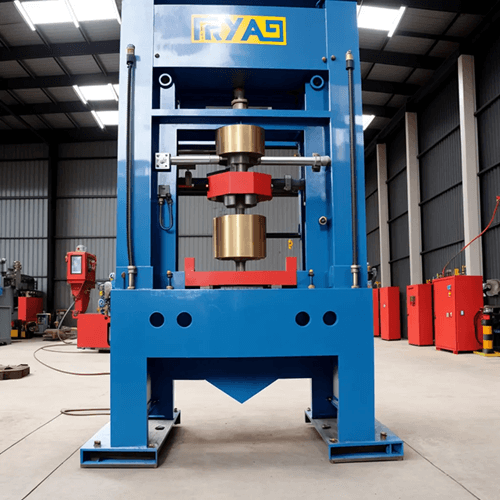

Regular sharpening is essential for maintaining the sharpness and effectiveness of groundhog foundation drilling tools. Invest in high-quality sharpening tools and equipment, such as sharpening stones, files, or grinders, suitable for the specific type of tool being sharpened. Follow manufacturer guidelines and recommended techniques for sharpening to ensure optimal results and avoid damaging the tools.

Proper Handling and Usage:

Proper handling and usage practices play a significant role in preserving the sharpness and longevity of groundhog foundation drilling tools. Avoid excessive force or misuse that can cause premature wear and dullness. Train personnel on proper handling techniques and encourage regular feedback and communication to identify and address any issues promptly.

Regular Replacements:

Despite proper maintenance and care, groundhog foundation drilling tools will eventually wear out and lose their sharpness over time. Establish a regular replacement schedule based on usage frequency, wear patterns, and manufacturer recommendations to ensure optimal performance and safety. Inspect tools regularly for signs of wear and replace them as needed to maintain efficiency and prevent costly downtime or accidents on the job site.

Conclusion:

Maintaining sharp groundhog foundation drilling tools is essential for ensuring efficiency, productivity, and safety in construction projects. By implementing regular inspection and maintenance routines construction professionals can prolong the lifespan of their tools and optimize performance on the job site. Check out for https://www.foundationdrillingtools.com/ for more about foundation tools.