What Kind Of Cold Forging Components Can I Get? Here Are Some

You could be wondering the kind of cold forging component you can get from the respective manufacturers, right? Well, the list can be endless since cold forging is used in making literary everything that is made of metal. For your information, cold forging entails subjecting a billet to pressure and compression with the intention of achieving specific shapes and forms. In this case, it is the preference of the manufacturer or the client that determines the kind of cold forging component to be made. However, a cold forging component can be made prior in readiness for selection by clients. Here are some cold forging component examples:

Metal Rods

Metal rods have been largely associated with the construction and infrastructural sectors. The said rods are processed through cold forging to ensure that they gain ample strength for industrial use. In this case, metal rods can be of different sizes in terms of length and girth. It depends on the intended use in selecting the metal rod that works best for a given situation.

Rivets

Indeed, rivets are an example of cold forging components that is popular anywhere around the world. Rivets are meant to join two pieces of metal such that a joint is created. For example, two guard rails along a highway can be joined together using rivets. It is notable that the size of rivets may vary depending on the intended use. Some of the rivets can be big while others are small.

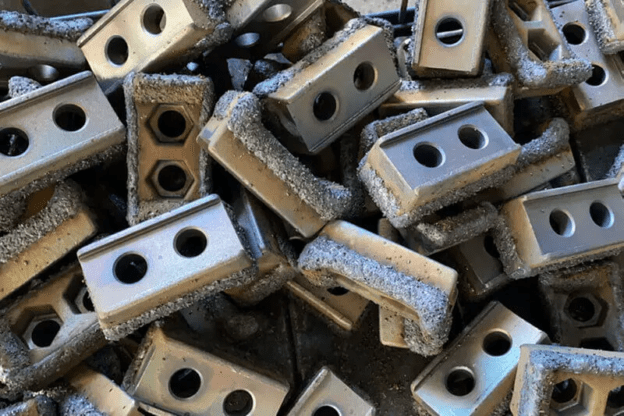

Bolts

Bolts play a similar role as rivets, only that bolts can be loosened and tightened depending on the intended usage. In some cases, the bolts can be large or medium. Or small sizes again, depending on the intended use. The cold forging process makes it possible to make strong custom bolts.

Guard Rails

As far as infrastructure is concerned, guard rails are considered integral. This is based on the main role they play in protecting individuals against serious accidents. Guard rails are made strong to ensure that they effectively play their respective roles.