Foundation drilling is a specialized construction process, requiring tools tailored for deep and precise drilling applications. When purchasing foundation drilling tools for the first time, there are certain pitfalls that can lead to wasted money, poor performance, or even safety hazards. Let’s delve into the five worst mistakes to avoid:

Ignoring Soil and Rock Conditions

Mistake: Choosing drilling tools without taking into account the specific geology of the project site. Different ground conditions, from sandy soils to hard rock, demand varied tool types and configurations.

Solution: Before purchasing, conduct thorough geotechnical investigations to understand the soil and rock profiles. This will guide you in selecting the right tools for the job, ensuring efficiency and reducing wear and tear.

Overlooking Tool Size and Specifications

Mistake: Buying foundation drilling tools that either exceed or fall short of the project’s depth and diameter requirements.

Solution: Plan ahead by understanding the exact dimensions of the foundations you’ll be drilling. Ensure the tools you select are suitable for the depth and diameter of the boreholes you intend to create.

Neglecting Manufacturer Reputation

Mistake: Opting for lesser-known brands or manufacturers without a proven track record in the industry.

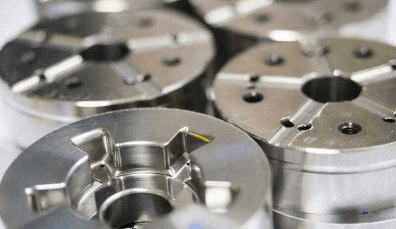

Solution: Go for manufacturers known for their durability, reliability, and after-sales service. While they might come at a premium, their tools often have a longer lifespan and better performance.

Failing to Consider Equipment Compatibility

Mistake: Purchasing foundation drilling tools without checking their compatibility with the drilling rigs or machines you intend to use.

Solution: Always verify that the tools you’re interested in can be easily integrated with your existing equipment. This ensures seamless operations and reduces the chances of malfunctions.

Skimping on Safety Features

Mistake: Investing in tools without adequate safety features, exposing operators to unnecessary risks.

Solution: Safety should always be a priority. Opt for tools with built-in safety mechanisms, such as anti-vibration systems, secure mounting points, and robust materials. Additionally, ensure that the manufacturer provides comprehensive usage guidelines and safety protocols.

If planning to buy drilling tools for the foundation and other purposes, check out the shared link.