Flexographic printing has emerged as a popular and versatile printing technique, especially for packaging materials. It relies on high-quality flexographic printing plates to produce vibrant, precise, and consistent prints. These plates play a crucial role in the printing process, affecting the overall print quality and efficiency. In this article, we will explore five essential features that define good flexographic printing plates.

Material Durability

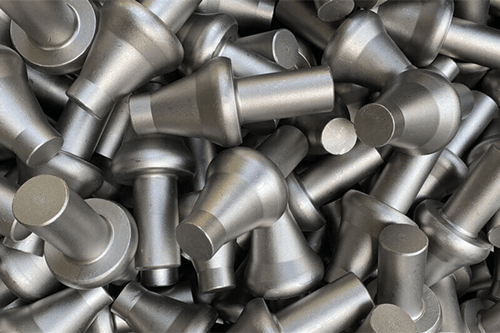

One of the primary characteristics of good flexographic printing plates is their durability. The plates should be made from robust and resilient materials capable of withstanding the rigors of high-speed printing. High-quality plates are typically constructed using photopolymer or rubber materials, which exhibit excellent resistance to wear and tear. These materials ensure the longevity of the printing plates, enabling them to produce consistent prints over an extended period.

Precise Imaging

Another crucial feature of good flexographic printing plates is their ability to reproduce precise and sharp images. The plates should possess excellent imaging capabilities, allowing them to transfer the intricate details of the artwork onto the printing substrate. Advanced plate manufacturing techniques, such as laser engraving or digital imaging, can achieve this level of precision. The ability to accurately reproduce fine lines, text, and halftone images ensures the production of high-quality prints with exceptional clarity.

Consistency

Consistency in print quality is vital in flexographic printing, especially for large-scale production runs. Good flexographic printing plates offer excellent consistency, ensuring that each print matches the desired color, tone, and sharpness. Plates with consistent characteristics minimize variations and help maintain the integrity of the printed design from the beginning to the end of a print run.

Dimensional Stability

To prevent print distortions, good flexographic printing plates should exhibit excellent dimensional stability. Dimensionally stable plates provide accurate and repeatable positioning of the printing image, resulting in clean and sharp prints without misalignment or blurring issues.

Chemical Resistance

Good flexographic printing plates should possess high chemical resistance. Plates with superior chemical resistance can withstand exposure to aggressive solvents and cleaning agents without swelling, deforming, or deteriorating. This resistance ensures the longevity of the plates and prevents any adverse effects on print quality caused by chemical interactions.

You can check out the best flexographic printing plate here.