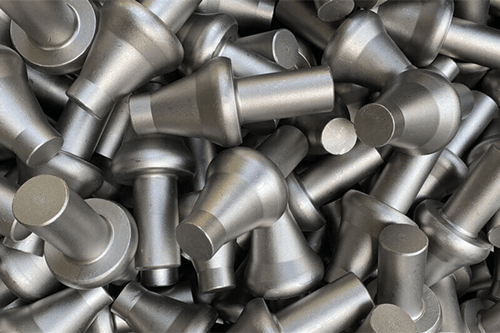

Foundation drilling tools are essential equipment used in construction and engineering projects to create deep and stable foundations for buildings, bridges, and other structures. These tools are subjected to rigorous wear and tear during their operation, which can lead to reduced efficiency and increased downtime if not properly maintained.

Below are 5 practical ways to extend the lifespan of foundation drilling tools, helping construction companies save on replacement costs and enhance overall project productivity.

Regular Inspection and Maintenance

One of the most critical aspects of extending the lifespan of foundation drilling tools is regular inspection and maintenance. Before each use, thoroughly inspect the tools for signs of damage, excessive wear, or any other issues that may affect their performance. Keep an eye out for worn-out teeth, cracks, or deformities, and promptly replace or repair any damaged components.

Proper Cleaning Procedures

During foundation drilling, these tools often encounter abrasive materials, debris, and soil that can accumulate on their surfaces. Regular cleaning is vital to prevent these particles from causing unnecessary wear and corrosion. However, avoid using harsh chemicals that may deteriorate the tool’s coatings or materials.

Correct Operating Techniques

Educating and training the operators on proper operating techniques can significantly impact the lifespan of foundation drilling tools. Misuse or improper handling can subject the tools to undue stress and strain, leading to premature wear and damage. Ensure that operators are aware of the recommended drilling parameters, including rotation speed, feed pressure, and torque settings, to ensure safe and optimal performance.

Temperature Considerations

Temperature and lubrication play crucial roles in extending the lifespan of foundation drilling tools. High temperatures generated during drilling can cause tool components to expand and contract rapidly, leading to micro-cracks and material fatigue. To combat this, consider using tools made of heat-resistant materials or employing cooling systems during drilling operations. Regularly inspect lubrication systems and ensure they are functioning optimally.

Proper Storage and Handling

Even when not in use, foundation drilling tools require careful handling and storage to maintain their performance and integrity. Store the tools in a dry and protected environment, away from direct sunlight, extreme temperatures, or corrosive substances.

https://www.foundationdrillingtools.com/ has a vast collection of high quality and affordable foundation drilling tools.